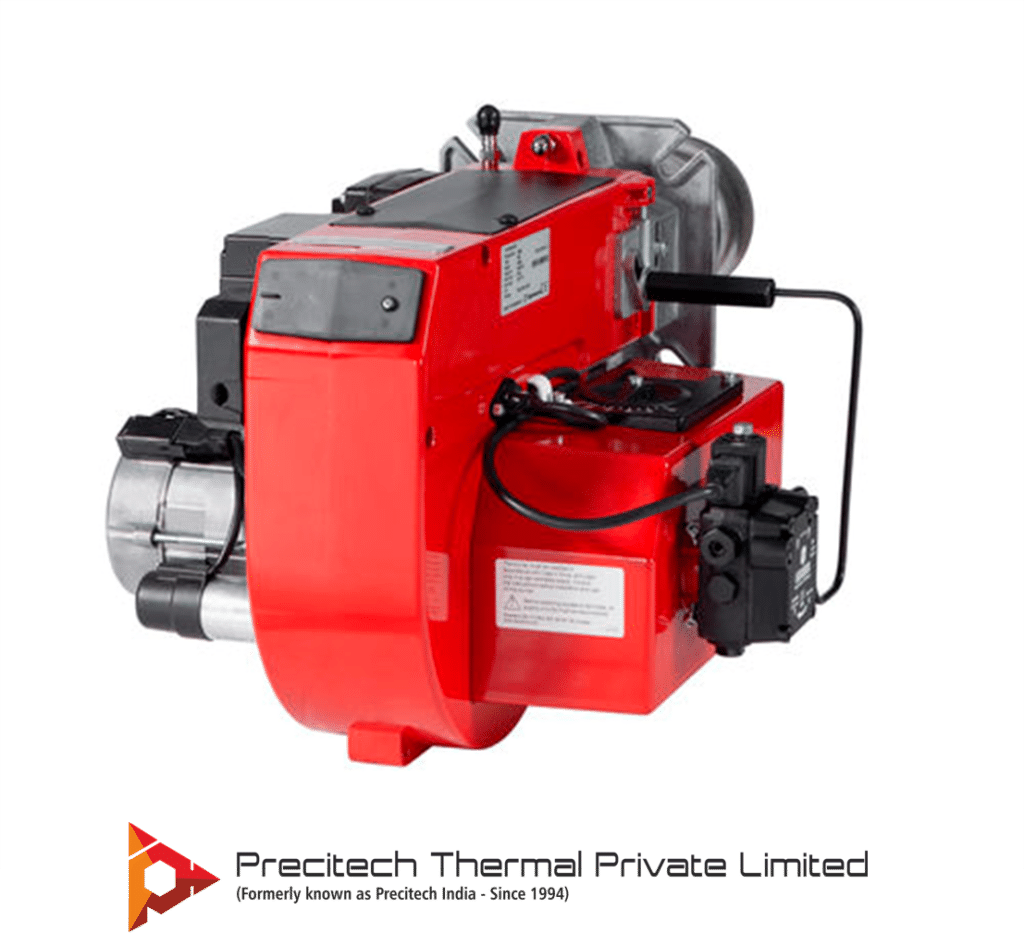

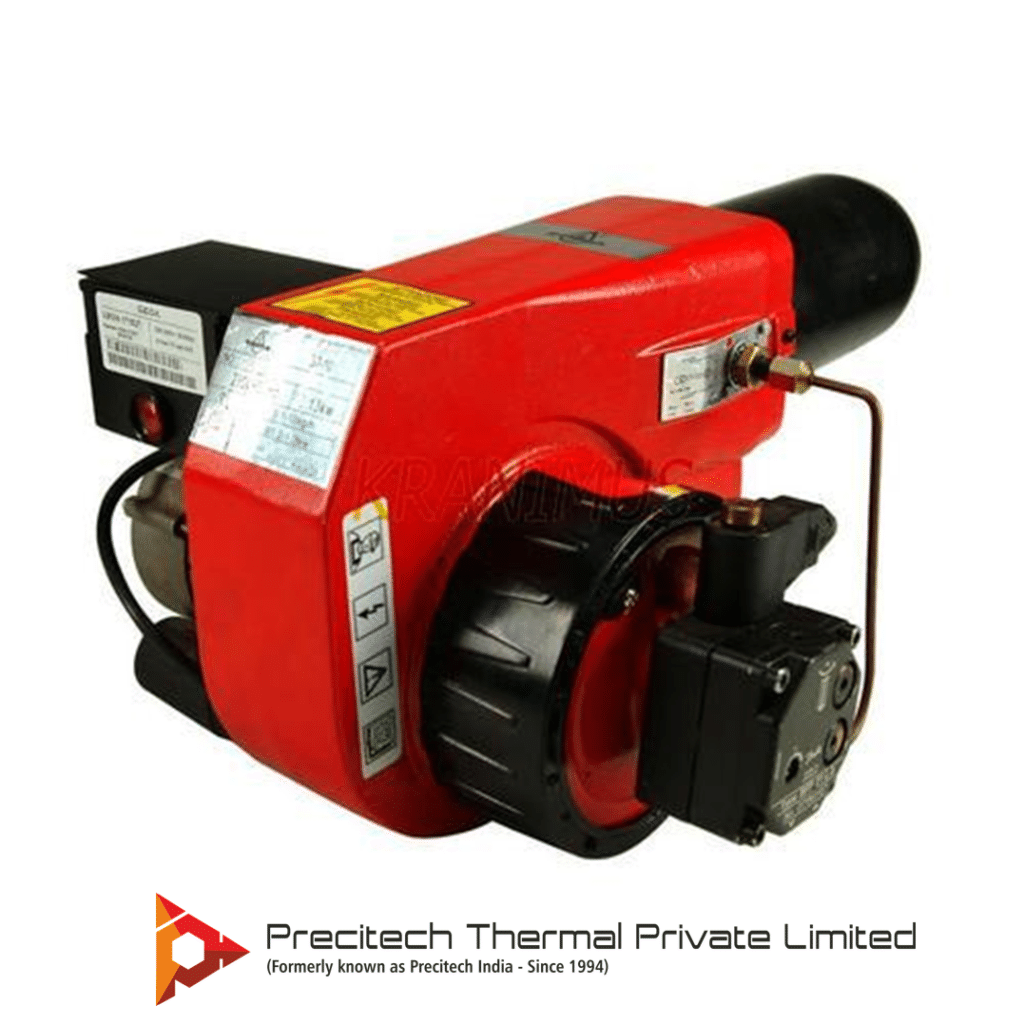

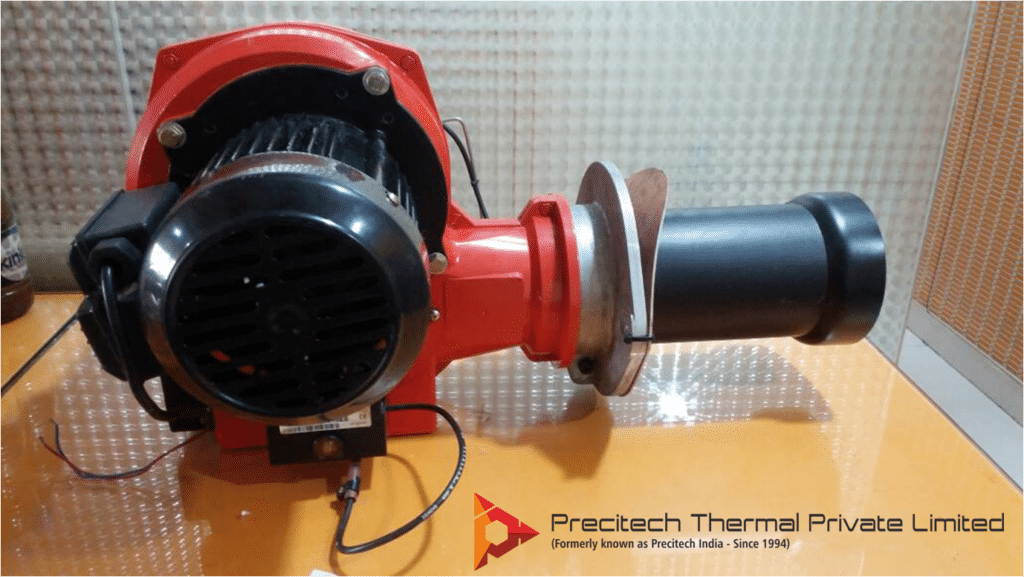

oil burner

oil burner Specification

- Condition

- New

- Type

- Industrial Oil Burner

- Usage

- Boiler/Furnace Heating

- Structure

- Horizontal

- Pressure

- High Pressure

- Style

- Automatic

- Material

- Mild Steel

- Temperature Range

- Up to 1500°C

- Power Supply

- 230 V/50 Hz

- Burner Capacity

- 10,000 to 10,00,000 kcal/hr

- Flame Monitoring

- Photo Cell

- Combustion Efficiency

- Up to 95%

- Mounting

- Flange Mounted

- Ignition System

- Automatic Electric Ignition

- Atomization

- Pressure Jet / Rotary Cup

- Application Industries

- Boilers, Furnaces, Ovens, Hot Air Generators

- Control

- Fully Automatic / Semi-Automatic

- Air Supply

- Integrated Blower

- Fuel Type

- Light & Heavy Oil

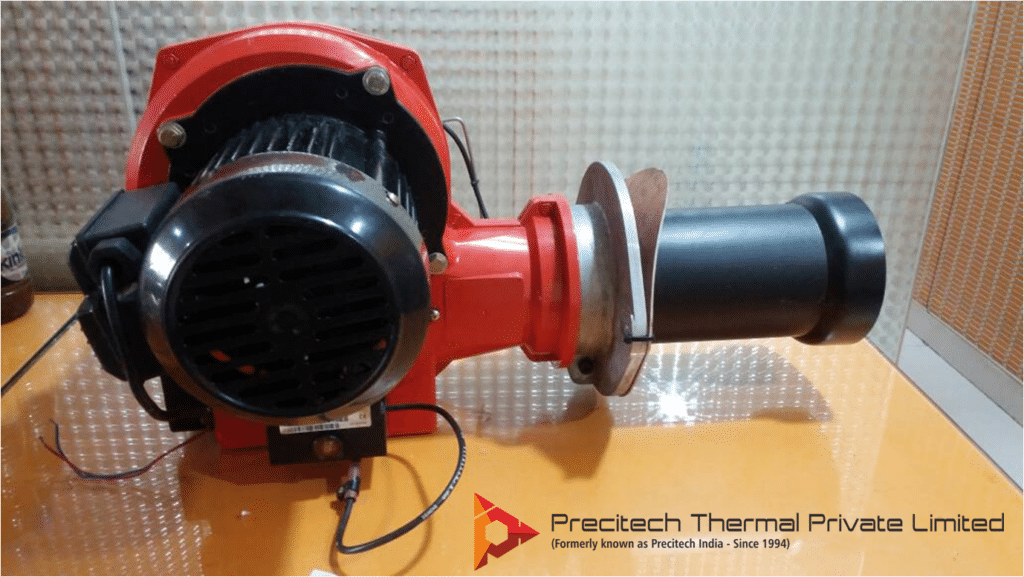

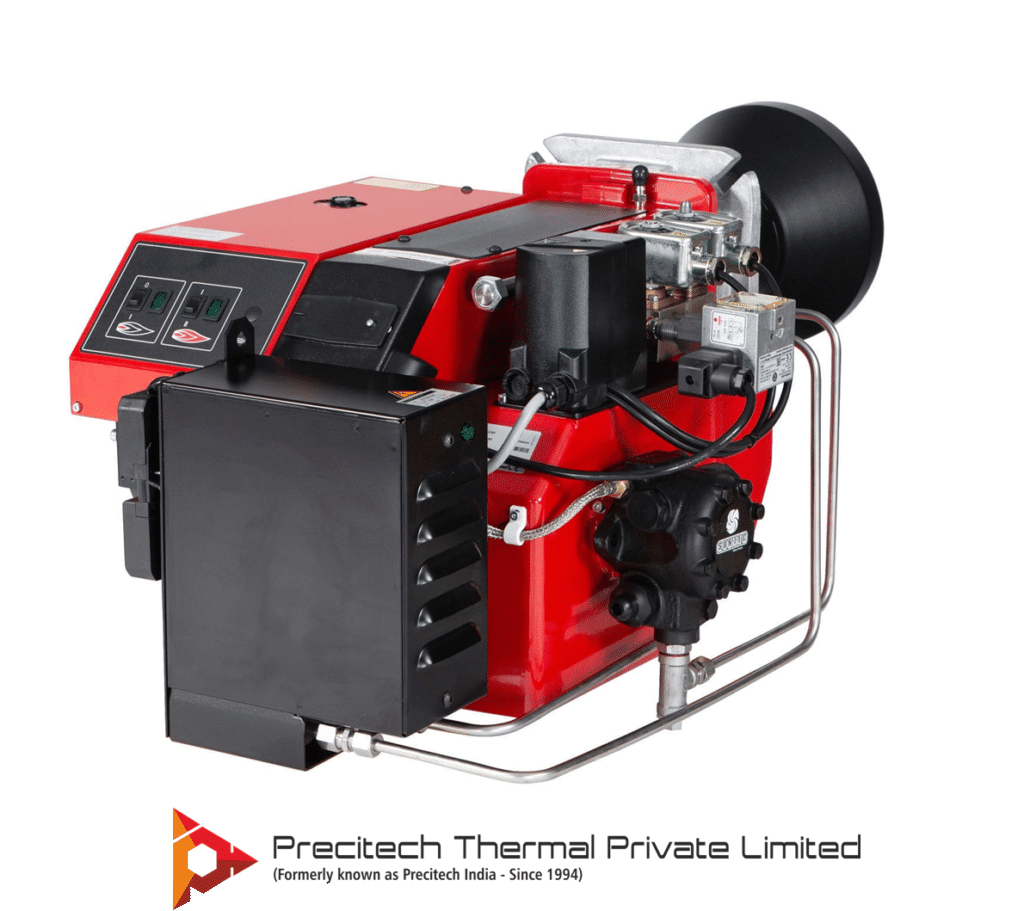

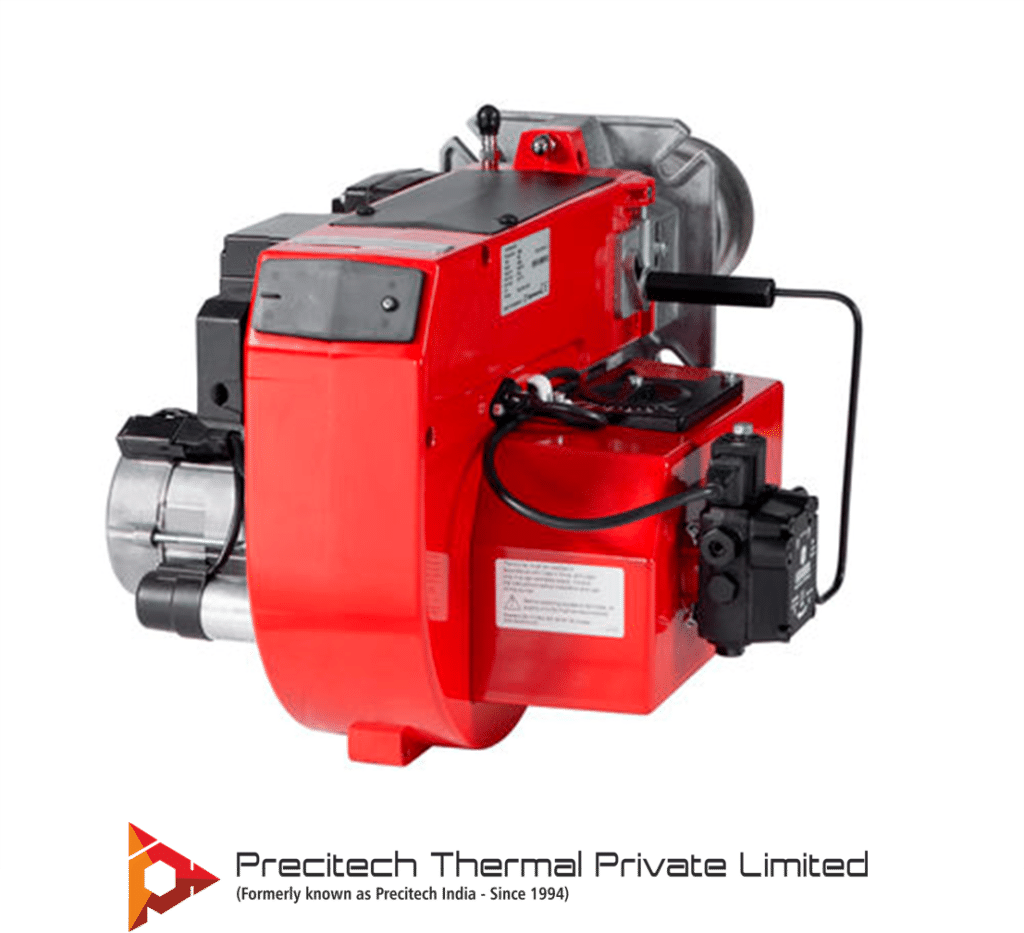

About oil burner

An oil burner is a part attached to an oil furnace, water heater, or boiler. It provides the ignition of heating oil/biodiesel fuel used to heat either air or water via a heat exchangerFurnace Oil Burner, FO Oil Burner, Oil Burner, Burner, Automatic Monoblock Burner, Monoblock Burner Oil Furnace Burners are well known for their reliability, efficiency, and performance. Low emissions, standards, and regulations are our keystones, Our product development always focuses on quality to ensure that we always have a reliable burner before we introduce it to the market.

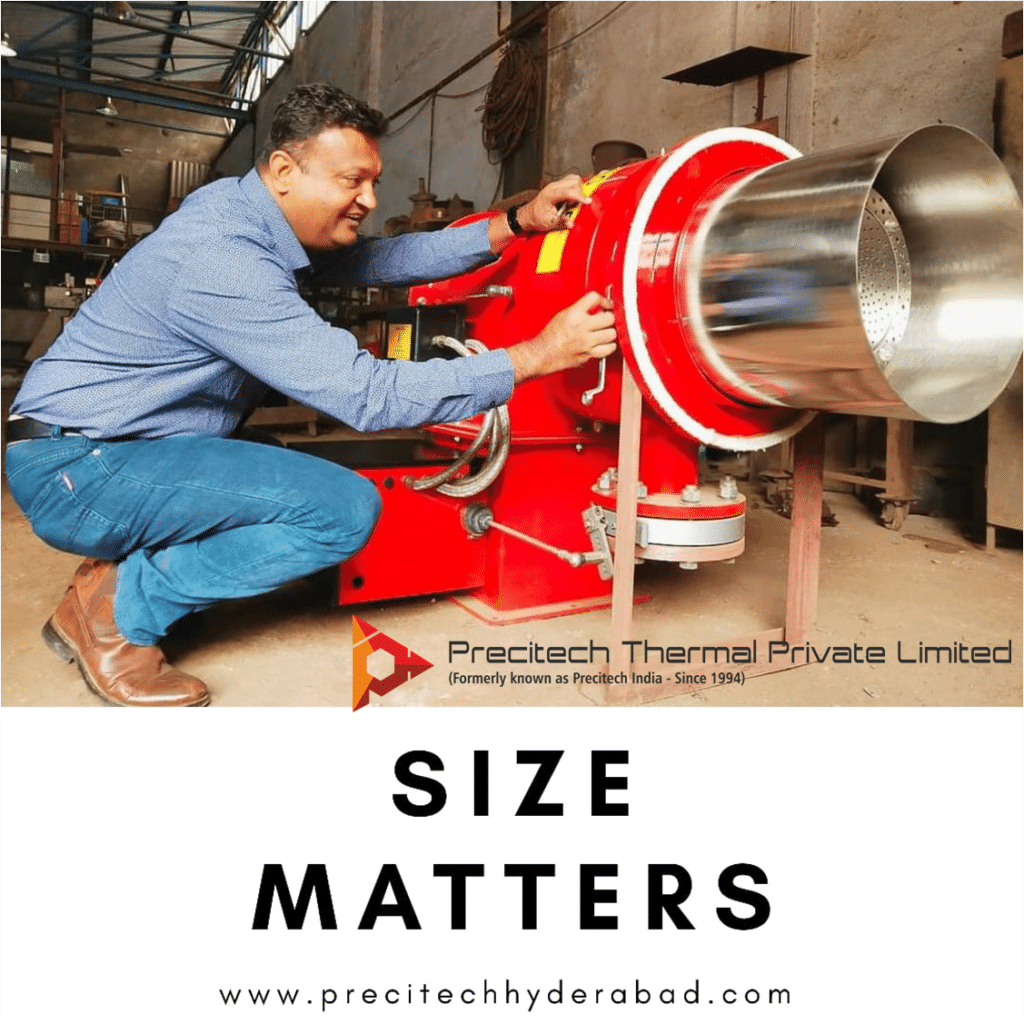

Versatile Performance for Varied Applications

Engineered for high-pressure, high-temperature operation, this industrial oil burner seamlessly adapts to different heating tasks across boilers, furnaces, ovens, and hot air generators. Its wide capacity range and advanced automation ensure efficient and reliable operation, maximizing productivity in demanding industrial environments.

Advanced Ignition and Monitoring Technology

Equipped with an automatic electric ignition system and photo cell-based flame monitoring, the burner guarantees safe and quick start-up every time. With integrated blower for optimal air supply and options for either pressure jet or rotary cup atomization, it ensures consistent combustion and low maintenance requirements.

FAQs of oil burner:

Q: How does the automatic electric ignition system enhance the burners operation?

A: The automatic electric ignition system simplifies start-up, offering reliable and quick ignition without manual intervention. This feature minimizes downtime and enhances safety by ensuring consistent flame establishment every cycle.Q: What industries can benefit from using this oil burner?

A: Industries such as power plants, manufacturing, food processing, and ceramics commonly use these burners for boilers, furnaces, ovens, and hot air generators, leveraging their robust performance and adaptability to diverse heating needs.Q: When should I choose a pressure jet atomization over a rotary cup system?

A: Pressure jet atomization is ideal for handling lighter oils and precise combustion control, while rotary cup systems excel at burning heavier oils and operating with varying fuel viscosities. Selection depends on fuel type and specific process requirements.Q: Where is this burner typically mounted during installation?

A: This burner is designed for flange mounting, meaning it can be securely attached to the front of boilers, furnaces, or ovens. The sturdy horizontal structure ensures compatibility with standard industrial heating equipment.Q: What maintenance processes are recommended to ensure optimal performance?

A: Regular inspection of the photocell flame sensor, cleaning of the atomization components, and routine checks of the blower and ignition system are vital. Scheduled maintenance not only improves efficiency but also extends the burners operational life.Q: How can fully automatic and semi-automatic control options benefit operations?

A: Fully automatic controls streamline the heating process with minimal manual oversight, improving operational efficiency, while semi-automatic options provide flexibility for operator intervention when needed, catering to diverse process requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Burners Category

BOILER OPTIMIZER

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard

Condition : New

Usage : Industrial

Material : Steel

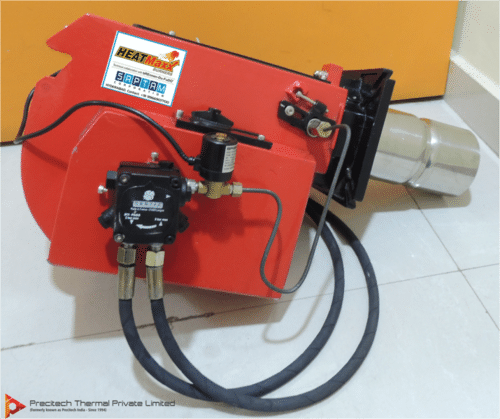

industrial heatmax burner

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard

Condition : New

Usage : Industrial

Material : Steel

E WASTE SHREDDER

Price 55000 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard

Condition : New

Usage : Industrial

Material : Steel

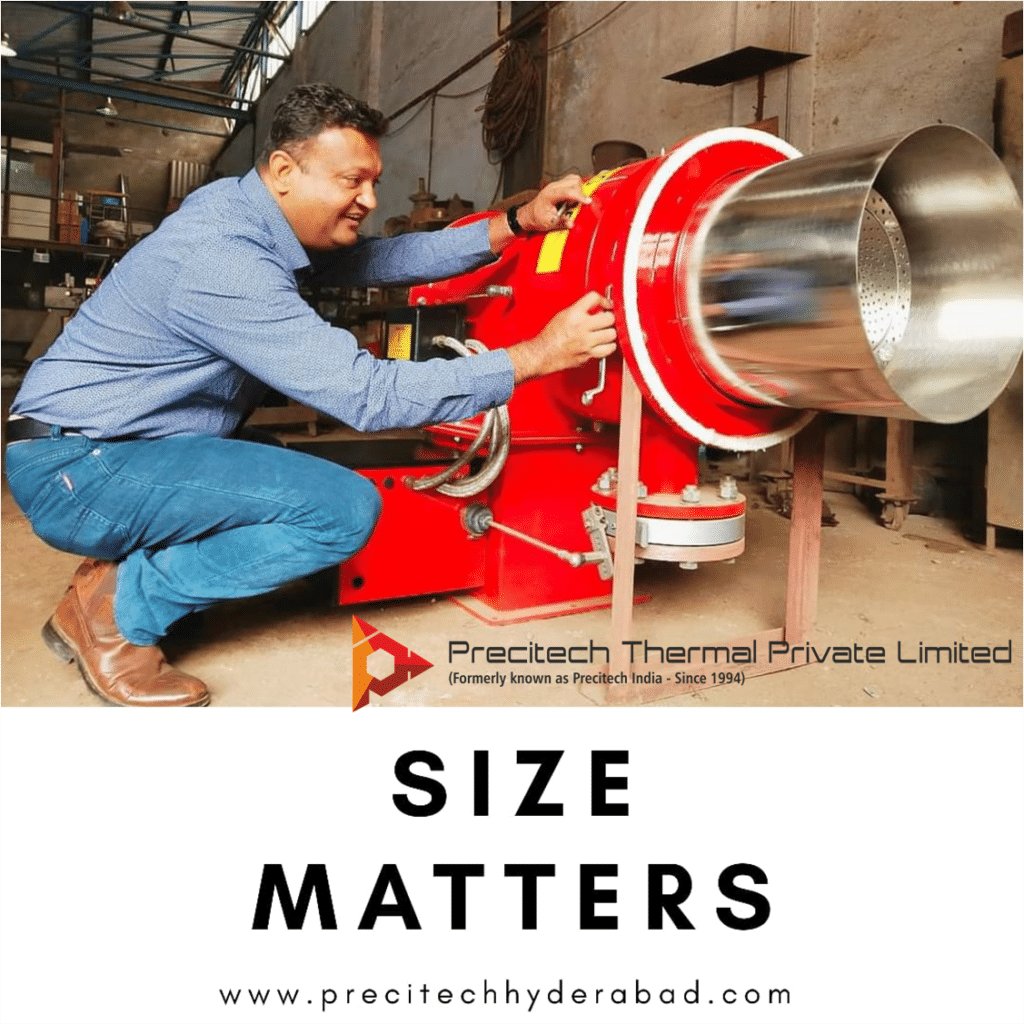

heatmax burner

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard

Condition : New

Usage : Industrial

Material : Steel

GST : 36AALCP9547K1ZM

Send Inquiry

Send Inquiry Send SMS

Send SMS