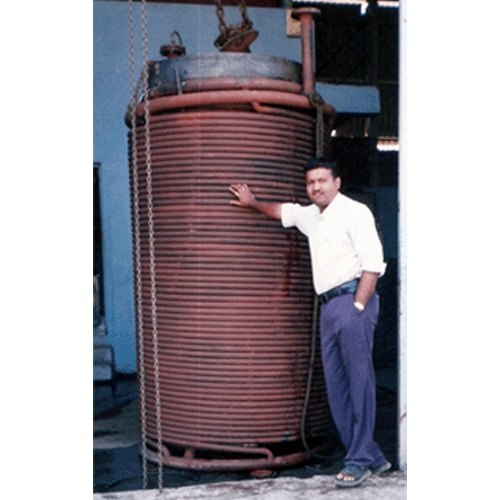

Coil Type Steam Boilers

Coil Type Steam Boilers Specification

- Fuel Consumption

- Varies, e.g. approx. 1275 kg/hr (depends on model/capacity)

- Condition

- New

- Style

- Coil Type

- Heat Efficiency

- Up to 85%

- Life Span

- More than 10 Years

- Pressure

- Up to 10.54 kg/cm

- Fuel Type

- Diesel, LPG, Natural Gas, Dual Fuel

- Capacity

- 50 kg/hr to 2000 kg/hr

- Voltage

- 415 V

- Output

- Dry Saturated Steam

- Temperature

- Up to 180C

- Material

- Mild Steel, Stainless Steel

- Part Type

- Industrial Steam Boiler

- Dimension (L*W*H)

- Custom sizes available (typical: 1800 x 1250 x 1950 mm)

- Function

- Steam Generation for Process and Heating Applications

- Ignition System

- Automatic

- Water Feed Type

- Automatic Feed System

- Surface Treatment

- Powder Coated / Painted

- Application

- Food Processing, Chemical, Textile, Pharmaceutical, Paper

- Startup Time

- Rapid Less than 5 minutes

- Body Insulation

- Class Insulation Provided

- Automation Grade

- Automatic

- Emission Standard

- Meets latest environmental norms

- Safety Feature

- High/Low Water Level Protection, Pressure Controls

- Mounting Type

- Horizontal Mounting

- Control Panel

- Integrated Digital Control

About Coil Type Steam Boilers

"High quality Boiler Coil" is available at Preci-Tech India. Moreover, these can be acquired from us at market reasonable price differ According to Model & Accessories with ready Stock for any Capacity.Preci-Tech India the Manufacturers and supplier of Steam Boilers, Thermic Fluid Heating Systems, Incinerators, Autoclaves, Plastic Shredder, Hot Air & Water Generators, Specialized Heating Systems As Per Clients Requirement Etc.

Advanced Automation and Safety Features

Our steam boilers integrate automatic ignition, digital controls, and comprehensive safety systems, including high/low water level protection and precise pressure controls. These features collectively minimize manual intervention, improve operational safety, and provide peace of mind in critical industrial environments. The result is seamless and secure steam generation, optimizing user experience.

Exceptional Efficiency and Fast Startup

Achieving up to 85% thermal efficiency, our boilers are engineered for energy-saving performance. The coil type design enables rapid steam production, with startup times of under five minutes, making these units ideal for processes demanding quick response without compromising output stability or quality.

Flexible Applications and Custom Sizing

Serving a broad spectrum of industries-food, chemical, textile, pharmaceutical, and paper-these boilers support a variety of heating and processing needs. With custom dimensions (typically 1800 x 1250 x 1950 mm) and capacity options, users can select systems that precisely match their operational requirements and facility layouts.

FAQ's of Coil Type Steam Boilers:

Q: How does the automatic ignition and feed system benefit my operation?

A: The automatic ignition and feed systems eliminate manual start-up and water filling processes, ensuring a seamless, safe, and efficient operation. This automation reduces downtime and boosts productivity, making it ideal for demanding industrial schedules.Q: What makes this coil type steam boiler suitable for industries such as food processing and pharmaceuticals?

A: Our boiler provides reliable, dry saturated steam, precise temperature control up to 180C, and meets strict emission standards, which are crucial for consistent product quality and regulatory compliance in sensitive sectors like food and pharmaceuticals.Q: When can I expect steam generation after starting the boiler?

A: Thanks to its rapid startup capability, the boiler delivers steam in less than five minutes from startup. This quick response aids industries where immediate steam availability is essential for process continuity.Q: Where can these steam boilers be installed?

A: With a horizontal mounting design and custom sizing available, the boilers can be installed in various industrial facilities, accommodating a range of spatial requirements and operational setups across India.Q: What is the process for ensuring operator safety during operation?

A: Operator safety is prioritized by high/low water level protection and integrated pressure controls, alongside robust body insulation and an automatic shutdown feature in abnormal conditions, reducing risks of overheating or pressure buildup.Q: Which fuel types are supported by this steam boiler?

A: The boiler is compatible with diesel, LPG, natural gas, and dual fuel systems, providing flexibility to select the most economical and accessible energy source as per regional availability and cost considerations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steam Boiler Category

Thermic Fluid Boiler

Price 450000 INR / Number

Minimum Order Quantity : 5

Material : Mild Steel

Condition : New

Output : Other, Hot Thermic Fluid

IICT Electric Steam Boiler

Price 400000 INR / Unit

Minimum Order Quantity : 5 Units

Material : Stainless Steel

Condition : New

Usage : Industrial

Output : Steam

Medical Waste Incinerators

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Condition : New

Usage : Industrial

Electric Steam Boiler

Price 500000 INR / Unit

Minimum Order Quantity : 5 Units

Material : Stainless Steel

Condition : New

Usage : Industrial

Output : Steam

GST : 36AALCP9547K1ZM

Send Inquiry

Send Inquiry Send SMS

Send SMS